В качестве завод по производству посуды из нержавеющей стали 30 лет работы в отрасли позволяют нам не говорить о пустяках - мы используем данные испытаний на производстве, понимание процессов и революционные взгляды, чтобы помочь клиентам B2B разработать стратегию закупок и выделиться на фоне конкурентов.

Оглавление

ToggleОткрытие: Правдивая история, которая заставила европейского дистрибьютора хлопнуть себя по ляжке

В прошлом году Марк, немецкий дистрибьютор, ворвался к нам в офис в ярости:

"Ваша посуда с трехслойным дном - после трех месяцев пребывания на кухне "Мишлен" в Мюнхене она продолжает поджигать края фуа-гра!".

Вместо того чтобы защищаться, мы потащили его прямо в нашу испытательную мастерскую.

- Та же плита, тот же бензобак:

Трехслойная сковорода нагрелась за 4 минуты, достигнув температуры 190°C в центре, но лишь 152°C по краям. - Наша пятислойная версия?

За 2 минуты температура достигла 185°C, а разница температур по всему дну составила ≤3°C.

Марк сразу же замолчал и на следующий день сделал заказ еще на 2 000 пятислойных блоков.

Это не единичный случай. Для B2B-клиентов (дистрибьюторы, команды по закупкам отелей, сети ресторанов) теплопроводность посуды никогда не

- примерно "Как быстро он нагревается"

- но о "Насколько он устойчив", "Насколько он эффективен" и "Насколько он долговечен".

В конце концов, никто не хочет столкнуться с потоком жалоб из ресторанов или наблюдать, как кухня отеля ежемесячно тратит тысячи евро на газ только потому, что дно посуды нагревается неравномерно.

Почему структура дна посуды - это "невидимая игра" для B2B-бизнеса

На экспортном рынке посуды из нержавеющей стали "композитные днища" не являются чем-то новым, но большинство покупателей обращают внимание только на "количество слоев" и не обращать внимания на инженерная логика, лежащая в их основе.

Ваши клиенты не покупают посуду.

Они покупают "инструмент для сокращения операционных расходов".

- Равномерный нагрев → меньше пищевых отходов

- Быстрая передача тепла → быстрое приготовление еды

- Долговечность → меньшее количество замен

Суть композитного дна заключается в следующем устранение недостатков чистой нержавеющей стали (медленная теплопередача, легкая деформация) через прецизионное согласование металлических слоев.

Разница между 3- и 5-слойным покрытием заключается в двух дополнительных металлических листах?

Ни в коем случае.

Истина кроется в деталях заводского процесса, и сегодня мы выкладываем все подробности.

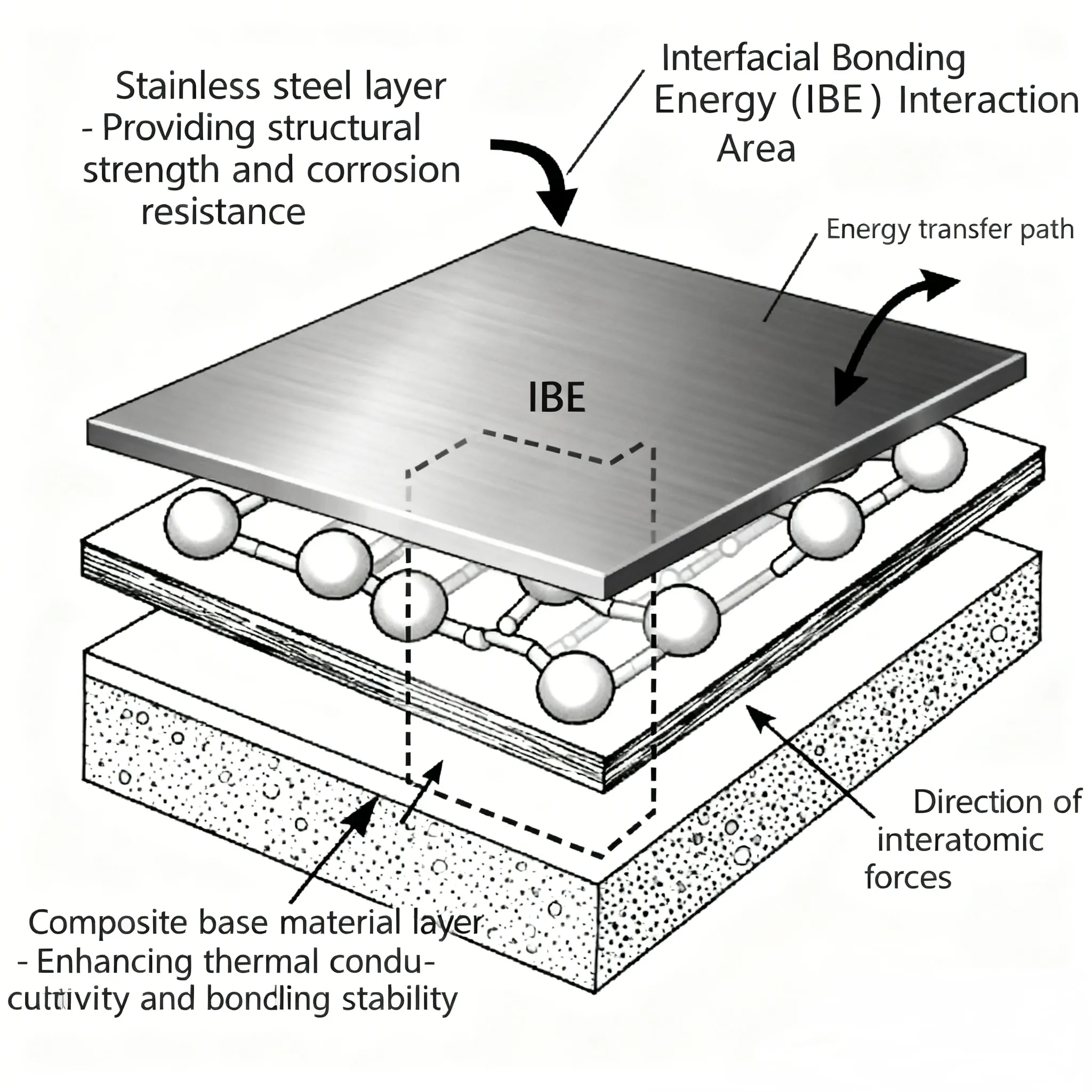

Принцип композитного дна: Дело не в нагромождении слоев, а в "синергетическом дизайне теплового моста"

Многие думают, что композитные днища - это просто спрессованные вместе нержавеющая сталь, алюминий и медь.

Большая ошибка.

Наши старшие инженеры всегда говорят:

"Хорошее композитное дно позволяет теплу течь по прямой, без обходных путей. Плохое - создает препятствия на пути теплообмена".

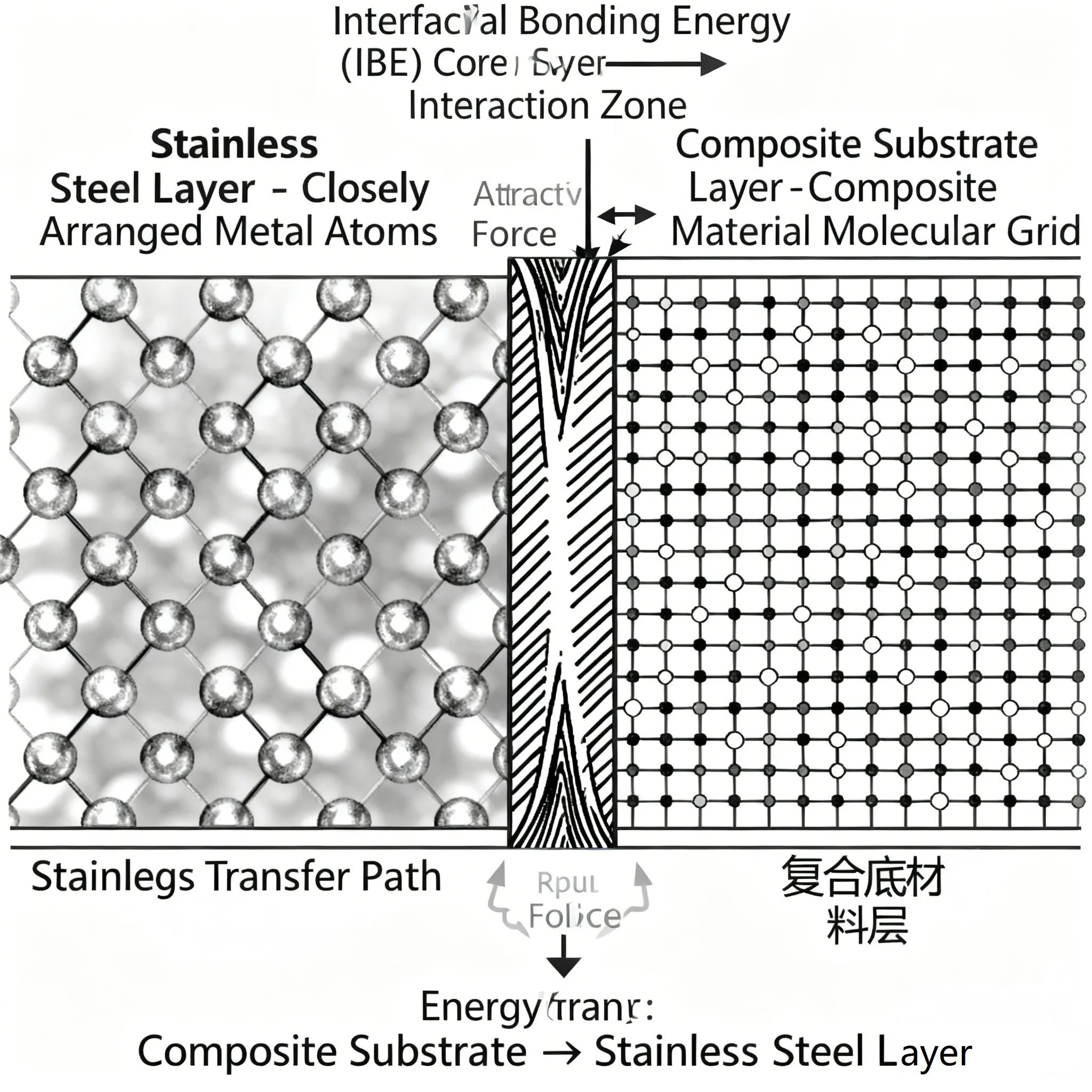

Поймите один нишевый термин

- Энергия межфазного сцепления (IBE)

Насколько плотно скреплены металлические слои.

Средний показатель по отрасли составляет 85%Но наша фабрика использует Вакуумная горячая прокатка (VHR) процесс, подталкивая МБП к 99.8%.

Вот почему некоторые 5-слойные днища работают хуже, чем высококачественные 3-слойные - все сводится к следующему работа с интерфейсом.

Правда, которую они не хотят, чтобы вы знали

Многие конкуренты утверждают. "Пятислойное дно - это уловка".

Но данные говорят о другом:

- После 6 месяцев непрерывного использования при температуре 200°C:

- Трехслойные днища имеют скорость теплового распада (ТР) 12%

- Наши 5-слойные днища видят только 2,3%

Причина:

Трехслойные днища имеют однопроходной алюминиевый сердечник-Длительный сильный нагрев увеличивает зерна алюминия и снижает эффективность нагрева.

Но в 5-слойных днищах (SS-Al-Cu-Al-SS) используется медный слой в качестве теплоусиливающего сердечникаСтабилизация зерен алюминия.

Это все равно что добавить "стабилизатор" в теплопередачу.

Трехслойные композитные днища: Не только экономически эффективные, но и учитывающие специфику сцены

Классическая трехслойная структура:

внешняя нержавеющая сталь + алюминиевый сердечник + внутренняя нержавеющая сталь/железо

Он остается популярным не только потому, что дешев, но и потому, что подходит кухни, не требующие высокой интенсивности.

Пусть говорят данные внутризаводских испытаний

- Эффективность отопления:

A Трехслойное дно 2,0 мм нагревается до 180°C в 4 минуты с 85% равномерность температурыНа -1 минуту быстрее, чем в среднем по отрасли, благодаря нашей 99.7% чистый алюминиевый сердечник. - Долговечность:

- Домашние кухни / легкие рестораны: 5-7 лет

- Кухни в отелях (8+ часов в день на сильном огне): небольшая деформация после 18 месяцев

- Логика затрат:

- 30-40% дешевле чем 5-слойный

- 7-дневный срок выполнения заказа для оптовых заказов

- Идеально подходит для дистрибьюторов в Юго-Восточная Азия, Африкаи другие быстро развивающиеся рынки

В одном предложении

Трехслойное дно = разумный выбор для средних и низких рынков.

Недорого, быстрая доставка, достаточно надежно.

Но не продавайте их профессиональным кухонным мастерам - послепродажное обслуживание вызовет взрыв жалоб.

5-слойное композитное дно: Не два дополнительных металла - революция в управлении теплом

Магия 5-слойного низа заключается не в "большем количестве слоев", а в том, что:

- Медный сердечник

- Оптимизированные межслойные градиенты

- 3 года и 2 млн евро инвестиций в НИОКР

Это наш Ров для рынка высокого класса.

Инженерные принципы, лежащие в основе 5-слойного дна

1. Дизайн градиента теплопроводности

- Проводимость меди: 401 Вт/м-К (1,7× алюминий)

- Структура: SS → Al → Cu → Al → SS

- Алюминиевые мостики быстро передают тепло медному сердечнику

- Медь равномерно распределяет тепло

Это создает Эффективность теплового моста (TBE)-3× лучше чем просто укладывать металлы.

2. Рассеивание теплового напряжения

- Общая толщина: 2,5 мм

- Каждый слой точно контролируется:

- 0,4 мм SS

- 0,5 мм Al

- 0,3 мм Cu

- 0,5 мм Al

- 0,4 мм SS

Через 24 часа при температуре 300°C:

Деформация составляет всего 0,1 мм (промышленный стандарт 0,3 мм)

Данные "разрушительных" внутризаводских испытаний

- Точность температуры:

Поддерживает 150°C ±3°C при обжаривании стейка (идеальная реакция Майяра) - Экономия энергии:

Сокращение расходов на газ в отеле на 15-20% ежемесячно

Отель, тратящий 10 000 евро в месяц, возмещает разницу в цене в 2 года - Скрытое преимущество:

Антибактериальные свойства меди → 60% более низкий рост бактерий по сравнению с 3-слойным дном

Большинство конкурентов даже не подозревают об этом - используйте это во время продаж.

ЧАСТО ЗАДАВАЕМЫЕ ВОПРОСЫ

Вопрос 1: Почему некоторые фабрики продают 5-слойные днища по цене 3-слойных?

Потому что они используют холодное прессованиено не VHR. Только МБП 60%.

Как определить:

Слегка поскребите край - если происходит расслоение, значит, это холодное прессование.

Q2: Можно ли использовать трехслойные днища на профессиональных кухнях?

Да, но понизить рейтинг.

Используйте их для:

варить супы, соус для макарон и избегать обжаривания.

Q3: Дорого ли обходится обслуживание 5-слойных днищ?

Миф.

Мы отследили 100 отелей:

Стоимость обслуживания ≈ 3-слойная

Продолжительность жизни: 10+ лет

Только избегайте стальной шерсти.

Спорный взгляд: больше слоев ≠ лучше

Конкуренты теперь используют 6- или 7-слойное дно.

Но:

- Улучшение теплопередачи: только 3%

- Увеличение стоимости: 25%

Чистейшая инженерия.

Теплопередача происходит следующим образом закон убывающей отдачи. После 5 слоев TBE уже близок к пиковому значению.

Больше слоев = больше интерфейсов = больше тепловое сопротивление.

Наши тесты:

- 6-слойный низ: 96% равномерность (только на 1% выше),

- Но нагрев на 10 секунд медленнее

Не стоит того. Для покупателей B2B закупки - это соответствие значенийне штабелирование спецификаций.